Tool Correction System / for Special-purpose Machine

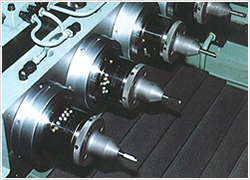

Radial Setting Head

Product Outline

The demand for high precision in machining process is increased more and more. To keep preciseness of the processed bore diameter, Tool Correction System is necessary. With this product, Tool Correction Control is carried out by the pressure balancing of the air pressure servo and the power boosting of the oil pressure. The elastically deformable Setting Head is radially deformed in micron level. Even after repetitive use, this Setting Head provides a stable linearity in proportion with no residual stress inside or metal fatigue.

Product Features

- Simple principle using Hooke's law F (power) = κ (modulus of elasticity)・ X (displacement).

- Boosts and transforms highly-precise control air pressure to high oil pressure. Force (F) of more than 10,000N is transmitted to the Setting Head.

- Highly rigid elastic body (κ) with an extensive linearity based on the unique parallel-plate design.

- Without using mechanical structure (i.e. gears or screws), high-quality and highly-durable with no backlash and less deterioration.

Membrane Setting Head (for high-speed processing)

Product Outline

The Head part is made with the highly-rigid diaphragm-pivot-type elastically deformable body to lessen the influence of the stick-slip. This product provides Tool Correction performance with high proportionality by the precisely-controlled hydraulic power.

Product characteristic

- Highly-precise, high-quality and highly-durable with the same sort of control system as Radial Setting Head.

- Membrane (film)-type elastically deformable body to lessen the influence of centrifugal force for high speed processing.

- Reduced unbalance by pivot movement with the pivot point of the elastically deformable part.

- Best for plus/minus taper processing with no influence of the stick-slip.

Cylinder Boring Head

Product Outline

Downsized elastically-deformable design to keep high rigidity for deep hole processing. Minimal-length Setting Head. High productivity in high processing and high precision are on the same vector.

Product Features

- Downsized design of the proven Radial Setting Head.

- Reciprocating processing, i.e. push-processing in retraction mode or pull-processing in offset mode is possible.

- Both Finish and Semi-finish processing available with one holder. Highly precise processing with less influence from heat deformation and residual stress is provided by 4-pass processing.

- The tip part is a rigid structure, which makes the high frequency vibration characteristics better and contributes to the longer tool life.

- In combination with the vibration analysis we’re proud of, we can offer the best processing condition for realization of high precision.

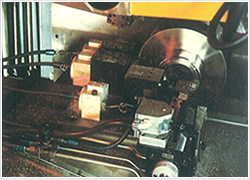

Micron Setting Tool Holder

Product Outline

This holder is a component of the Tool Correction System and composed of the uniquely designed Setting Head having air servo mechanism and rigid parallel elastic body for lath processing. The system with this holder offers: Micron-level tip adjustment High repeatability of less than 1 micron Simple and rapid (less than 1 second) offset performance This product with the easy operation is appreciated by users of single-and multi-spindle automatic turning machine, single-function machine, copying lathe and special purpose machine for turning. The picture on the left shows a processing of a brake disc with this holder.

Product Features

- Highly-precise, high-quality and highly-durable with the same sort of control system as Radial Setting Head.

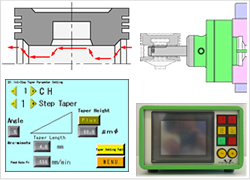

Hydraulic Servo Drive Control System

Product Outline

To meet the demand for processing of partly-tapered hole, this system provides highly accurate tip adjustment during processing. By combining a servo valve and a pressure sensor in the special hydraulic unit, direct hydraulic control is provided in semi-closed loop. The head is the Membrane Setting Head, which has less influence of the stick-slip. Highly precise increment/decrement of offset displacement available. Plus/ Minus taper processing from one direction is also possible. The Tool Correction Controller with the built-in sequencer has a user-friendly 5-inch display screen, on which parameters can be input with touch screen system.

Product Features

- The head is the Membrane Setting Head, which has no influence of the stick-slip.

- Precise hydraulic control using the special high-pressure hydraulic pump and servo valve.

- Offset hydraulic pressure is monitored by a sensor. Semi-closed loop through feedback to the controller. Real-time highly-precise tip control.