Tool Correction System / for General-purpose Machine

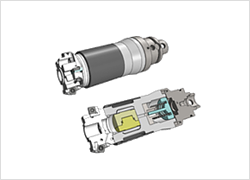

P/H type ATC Setting Head

Products Outline

Control Air Pressure is transmitted through the center-through hole or the special path in this Tool Correction Setting Head. This Setting Head has a structure that boosts pressure by converting air pressure to oil pressure. This structure provides equivalent level of system to the system for special-purpose machine. Air pressure, a control working medium, is transformed to oil pressure and boosted on the inside of the holder. The power deforms the elastically deformable body to provide an offset performance. It is a pneumatic and hydraulic pressure transformational system and offers 1-micron level offset performance with high responsiveness. Sequential processing of a set of large and small bores is possible with a step boring bar.

Product Features

- Designed for ATC and downsized, taking on the Tool Correction System for special-purpose machine.

- Has a pneumatic/hydraulic pressure transformation and boosting function inside. High offset performance is provided by only supplying control air pressure.

- For various ATC shank specifications.

- Axial center coolant possible.

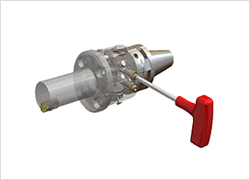

P/H type ATC Setting Head for Cylinder Boring

Products Outline

More compact elastically-deformable design to keep high rigidity for deep hole processing. Minimal-length Setting Head.

Product Features

- Downsized design of the proven Radial Setting Head.

- Reciprocating processing, i.e. push-processing in retraction mode or pull-processing in offset mode is possible.

- Both Finish and Semi-finish processing available with one holder. Highly precise processing with less influence from heat deformation and residual stress is provided by 2-pass processing.

- The tip part is a rigid structure, which makes the high frequency vibration characteristics better and contributes to the longer tool life.

- In combination with the vibration analysis we’re proud of, we can offer the best processing condition for realization of high precision.

- Focusing on the influence of processing heat displacement, important high-speed processing is realized based on the heat analysis.

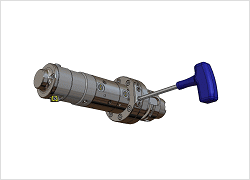

Push-type ATC Setting Head ζ-ONE

Products Outline

Controller-free push-type Tool Correction Setting Head. The holder has a plus and a minus button. By pressing these buttons in NC axis control, an offset performance of 1 micron/1 push is provided.

Product Features

- Manually operable by lightly pressing the buttons with a finger.

- With the hydraulic pressure boost and mechanical force multiplication mechanism, compact but high power and high rigidity. /li>

- Exchangeable to various ATC shanks.

- Available for axial center courant.

Push-type ATC Setting Head ζ-TWO

Products Outline

Designed for processing large and deep hole. Offset performance is provided by pressing the plus and minus buttons on the holder.

Oval elastically-deformable body, which axisymmetrically deforms, was specially developed. This product provides high-speed and highly-precise processing without losing balance at various offset ranges.

Product Features

- Possible for up to N=7,000rpm with the oval elastically-deformable body.

- Highly-precise 1-pass processing of pre-finish and finish with the two facing tips that provides an offset performance at the same value.

- Reduced high-frequency vibration with the unique cartridge design and the elastic body. Longer life of tip.

- Available for axial center courant.